X-RAY INSPECTION

X-ray detection is an increasingly prominent inspection method utilized in food production facilities, enhancing safety and brand protection. Aligned with LOMA’s core philosophy of “Designed to Survive®”, our engineering teams develop solutions based on key principles tailored for X-ray inspection systems in the food sector.

The integrated technology advancements significantly enhance image quality, facilitating a superior low density contaminants detection in food, such as glass, ceramic, bone, and rubber. Additionally, it provides more robust detection capabilities for harder contaminants, including metal and stainless steel.

SAFE – Ensures product safety for end consumers while promoting operational safety during use.

DURABLE – Engineered to withstand the rigors of any food production environment, Loma’s X5 series is tough, robust, and reliable.

FLEXIBLE – Designed to accommodate various inspection requirements, the X5 series features multiple inspection algorithms and innovative Adaptive Array Technology (AAT).

FRIENDLY – User-friendly and environmentally conscious, the X5 series facilitates ease of operation and contributes to a low cost of ownership.

For more than 20 years, LOMA SYSTEMS® has been at the forefront of X-ray technology development for food inspection. Drawing on extensive experience from numerous installations worldwide, catering to both large and small producers, LOMA has added a Dual Energy X-ray to the X5 Series.

The X5 range features a full-color touchscreen, multilevel password access and RFID on select models for secure data management, event logging for traceability, image optimization, AAT technology, and a host of additional advanced functionalities.

Why use X-ray Inspection technology

X-ray inspection is increasingly emerging as the preferred method for contaminant detection among factories adhering to stringent retailer codes of practice, as well as those seeking to offer ultimate protection for their brand.

X-ray Inspection systems offer a great range of benefits including:

Ability to detect a significantly broader spectrum of contaminants

- Excellent detection capabilities for ferrous, non-ferrous, and stainless-steel metal contaminants

- Dependable detection of glass, bone, ceramic or stone materials, dense plastics, product clumps, and other foreign bodies, contingent upon the relative densities of the contaminants.

Reliable inspection of products packaged in aluminium trays or metallized foil

- The X5 series can effectively detect stainless steel and non-ferrous materials in food packaged in metal foil or aluminium trays, without interference from the packaging itself.

Integrity verification of products being scanned

- X-ray systems can conduct simultaneous inspections of products, identifying missing items, detecting excess products by volume count, and performing x-weighing analysis.

To find out more about Loma's X-ray Inspection range download our brochure.

X-ray inspection FAQ's

Understand more about X-ray inspection, how it compares to metal detection and what it can do for your production.

X5DE Space Saver X-Ray Inspection

Designed to deliver superior accuracy, considerably minimizing false rejects while ensuring precise and adaptive imagery that enhances contaminant detection. It is available in 500mm belt width models and is perfect for products with a height of up to 180mm.Ideal for:

- Convenience Food | Food-to-Go

- Dairy and Egg Products

- Meat, Poultry & Fish

- Bakery

- Confectionery & Snack Foods

X5C Compact X-Ray Inspection

Designed for retail-packed food products, the X5C is the smallest X-Ray system available, with a machine length of 1000mm and offers first-class CCP protection in the smallest footprint possible - and Designed to Survive.Ideal for:

- Convenience Food | Food-to-Go

- Meat, Poultry & Fish

- Bakery

- Dairy and Egg Products

- Confectionery & Snack Foods

- Fruit, Vegetables & Nuts

- Other / General Industries

- Dried Foods, Cereals & Grains

- Pharmaceutical & Nutraceutical

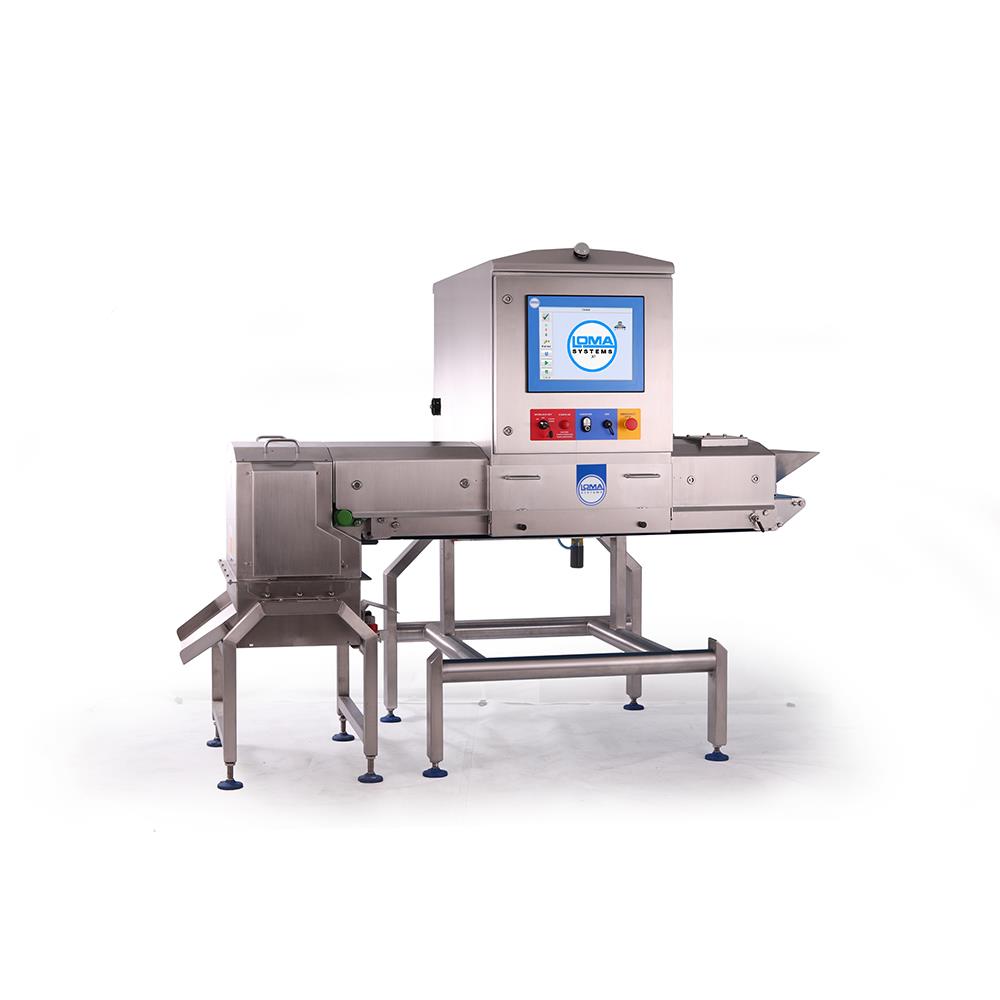

X5 Space Saver X-ray Inspection System

Designed to be integrated into line with optional free standing reject, it is available in 300mm and 500mm belt width models, and is perfect for products with a height of up to 180mm.Ideal for:

- Convenience Food | Food-to-Go

- Dairy and Egg Products

- Meat, Poultry & Fish

- Bakery

- Confectionery & Snack Foods

X5 Pack X-ray Inspection System

Designed to be integrated into line with built-in automatic reject and available in 300, 500 and 600 mm belt width models, the X5 Pack is perfect for a variety of unpackaged and packaged products.Ideal for:

- Convenience Food | Food-to-Go

- Dairy and Egg Products

- Meat, Poultry & Fish

- Bakery

- Confectionery & Snack Foods

X5 Pack Curtainless X-ray Inspection System

Designed for small, lightweight packaged or unsealed products, the X5 Pack Curtainless system is perfect for loose flowing or multi-lane X-ray inspection.Ideal for:

- Confectionery & Snack Foods

- Bakery

- Convenience Food | Food-to-Go

- Dried Foods, Cereals & Grains

- Pharmaceutical & Nutraceutical

- Other / General Industries

X5C & CW3 Check & Detect Combination System

The X5c & CW3 Check & Detect Combination System is designed for detecting contaminants and reducing giveaway in food products. This system is perfect for inspecting retail-packed convenience food, ready meals in foil trays and small end-of-line packaged goods up to 280mm wide by 110mm high.

Ideal for:

- Convenience Food | Food-to-Go

- Meat, Poultry & Fish

- Bakery

- Confectionery & Snack Foods

- Dairy and Egg Products

- Fruit, Vegetables & Nuts

- Other / General Industries

X5 Space Saver/CW3 Check & Detect Combination System

The X5 Spacesaver/CW3 Check & Detect Combination System is designed for detecting contaminants and reducing giveaway in food products. This system is perfect for inspecting retail-packed convenience food, ready meals in foil trays and small end-of-line packaged goods.

Ideal for:

- Convenience Food | Food-to-Go

- Meat, Poultry & Fish

- Bakery

- Confectionery & Snack Foods

- Dairy and Egg Products

- Fruit, Vegetables & Nuts

- Dried Foods, Cereals & Grains

- Other / General Industries

X5 Pipeline for Pumped Food Inspection

The X5 pipeline is perfect for inspection of a wide range of pumped and free flowing applications such as poultry, meat, slurries and sauces.Ideal for:

- Dairy and Egg Products

- Meat, Poultry & Fish

X5 SideShoot for Tall Product Inspection

The X5 SideShoot is perfect for inspection of a wide range of tall products such as yogurts, snacks, biscuits, and lightweight cans.Ideal for:

- Dairy and Egg Products

- Confectionery & Snack Foods

- Bakery

- Dried Foods, Cereals & Grains

- Other / General Industries

X5 Bulk Flow for Loose Food Inspection

Designed to be integrated into line with optional reject stations, the X5 Bulk Flow X-ray is perfect for loose and free flowing products.Ideal for:

- Dried Foods, Cereals & Grains

- Fruit, Vegetables & Nuts

- Other / General Industries

Need support or spare parts for your inspection product?