X5 4-inch Pipeline for higher volume inspection

Why do we need a 4-inch product

The 4-inch Pipeline X-ray detection system has been introduced to compliment the current pipeline range.Following our customer back innovation programme, our customers highlighted the need for a product with 4-inch couplings and higher throughput. While the current 2.5-inch and 3-inch products offered excellent contaminant detection, our customers required higher volume inspections.

Product Sectors

The X5 4-inch Pipeline is perfect for large hams, gammon, salami, corned beef, etc. Products made from re-formed muscle and protein. Plus, the X5 4-inch Pipeline is equally capabile with fast, free-flowing products such as jam, chutneys, soups or sauces, where you want to detect more than just metal.

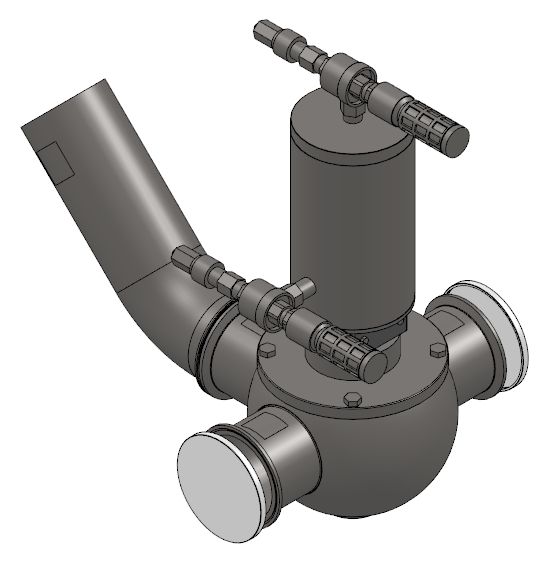

Our development journey of the 4-inch manifold:

The X-ray section is a rectangle, in effect, it changes the shape of the contents rather than compressing it. There is minimal reduction in flow or risk of back pressure issues. Plus, the feed to the X-ray section is on a gradual incline to aid flow and reduce back pressure.

Reject valve options

ARL suitable for 2.5-inch | 3-inch | 4-inch

Arc design for vacuum filler applications with strip-down cleaning suitable for whole muscle meat.

Lee Ball Valve

Whole muscle (raw meat) applications require a sharp cutting action, and a Lee Ball valve would be advisable.

The 4-inch Pipeline has all the flexibility of the X5 range

- Excellent Detection of Bone, Metals, Glass, and Stone. The X5 Pipeline provides the capability to inspect for bone, ceramic, glass,and dense plastics.

- In addition, it improves the metal detection levels, in comparison to a pipeline-based metal detector, detecting stainless steel, ferrous and nonferrous metals.

- Peace of mind that no contaminants will pass inspection.

- The X5 Pipeline includes an Icon-driven full-color touchscreen control interface with easy-to-use product learning and features and layout.

- Enhanced production data visibility.

- An easy-to-use capacitive 8 touchscreen Ensure the highest levels of regulatory compliance through real-time data collection. - Easy to recover data if required.

- Easy access to all machine areas. The IP69 comes as standard for harsh wash-down environments.Reduced risk of cross-contamination through poor cleaning regime.

- The easy-to-remove cassette makes cleaning and maintenance a walk in the park.

Ideal for these products

Downloads for the X5 4-inch Pipeline for higher volume inspection

To find out more about Loma's X-ray Inspection range download our brochure.

Additional Features

- Check product integrity including counting and missing items

- Features AAT Technology

- Manufactured with LOMA's "Designed to Survive" philosophy

- Lead free construction

Specifications

Material of Construction: 304 Brushed stainless steelSystem Length: 400mm (Without Reject)

Line Height Option: 750 - 1000mm (+/- 50 adjustment)

X-Ray Output: 100W (50kV 2 mA)

IP Rating: IP69K

Pipe Diameter ("): 2.5" | 3" | 4"

Speed Range: 20 - 80 m/min

Supply Voltages: 85 to 265 V, single phase 50/60Hz, neutral & amp;Earth

Cooling: Vortex (requires compressed air connection)

Operating Environment (standard): 10 - 35°C (50 - 95 °F)

Operating Environment (warm-up enabled): 0 - 10 °C (32 - 50 °F)

X-Ray Safety: Leakage less than 1 μSv/h

Reporting: Event, Batch, Shift

Data Retrieval: Via USB, Ethernet