End-of-line: Packaged Products

End-of-line inspection protects brands and the consumer

Loma produces a range of inspection equipment designed for the end of the production process where product is packaged and ready for shipment to the wholesaler or retailer. As part of a HACCP / food safety management plan, the systems normally form a Critical Control Point (CCP) and helps identify issues prior to the product being placed on the market.

Create a comprehensive CCP with a Combo System

Combination systems create a more comprehensive CCP and save factory space by combining a detection system (metal detector or X-ray) with a MID/R51 accredited checkweigher.

Improve robustness & sanitation with hygienic design

Hygienic system design forms a fundamental philosophy for ensuring an inspection system is easy to clean, as well as having the necessary robustness for a system to survive in a high-care factory environment. Loma’s systems are designed to have an IP66 ingress rating for low-pressure washdown or IP69K for high-pressure washdown conditions.

Maximise CCP integrity with Fail-Safe functionality

Fail-safe functionality are added features to an inspection system that help improve the security of contaminated products as well as improve the overall integrity of a Critical Control Point. Some functionality is industry best-practice, whereas others are essential for meeting Retailer Codes of Practice or for demonstrating a zero-tolerance attitude towards foreign body contamination.

IQ4 Metal Detector Conveyor

The IQ4 Conveyorized Metal Detector system is designed for packaged and loose products and can be supplied with full retail compliance.

X5C Compact X-ray Inspection

Designed with retail-packed convenience food in mind the X5C is the smallest X-Ray system available, with a machine length of 1000mm and offers first-class CCP protection in the smallest footprint possible - and Designed to Survive.

X5 Spacesaver X-ray Inspection

Designed to be integrated into line with optional free standing reject, available in 300mm and 500mm belt width models, the X5 SpaceSaver is perfect for packed products with a width of up to 250mm.

X5 Pack X-ray Inspection

Designed to be integrated into line with built-in automatic reject and available in 300, 500 and 600mm belt width models, the X5 Pack is perfect for a variety of unpackaged and packaged products.

Metal Detector Combination System

The metal detector combination system is designed for simultaneously detecting metal contaminants and reducing giveaway in food products. This system is perfect for inspecting a wide variety of food products, including retail-packed convenience food/ Food to Go and much more.

X5C & CW3 Check & Detect Combination System

The X5c & CW3 Check & Detect Combination System is designed for detecting contaminants and reducing giveaway in food products. This system is perfect for inspecting retail-packed convenience food, ready meals in foil trays and small end-of-line packaged goods up to 280mm wide by 110mm high.

X5 Spacesaver & CW3 Check & Detect Combination System

The X5 Spacesaver/CW3 Check & Detect Combination System is designed for detecting contaminants and reducing giveaway in food products. This system is perfect for inspecting retail-packed convenience food, ready meals in foil trays and small end-of-line packaged goods.

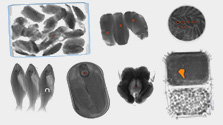

Increase Efficiency & Food Safety with X-ray Inspection Systems

- Better detection of metal in comparison to conventional metal detectors

- Able to inspect protein products packed within foil or metallized packaging

- Automate manual checks by using X-ray Object checking algorithms to identify product defects and missing items

- Can integrate into a Combo for combined detection and weighing at end-of-line