In-line: Bulk or Loose Products

Loma offer a wide range of food inspection systems for bulk or loose products within the protein industry. The systems vary depending on the application and will cover products such as chicken nuggets, joints of meat and large trays of protein product.

Optimize and automate the production process

Scanning products in-line which are either loose, unpackaged or bulk/large during processing helps to optimize factory processes by:

- Protects equipment: Protects down-line machinery from damage caused by harder contaminants damaging expensive processing and packaging equipment

- Reduces waste: Allows contaminated product to be isolated and dealt with prior to going through more costly processing stages and packaging

- Product efficiency: Allows for as much good product to be harvested back into production if found to not be contaminated

- Reduce giveaway: Monitoring in-line product weight can help provide indicators to optimize portioning and filling

Dual X-ray system inspecting loose chicken fillets

IQ4 Conveyorized Metal Detector identifies contaminated raw product by stopping on detect and alarming

A carriage retract is an alternative to a belt-stop / alarm reject and removes contaminated product from the line

View the Range of Bulk Systems

IQ4 Rectangular Metal Detector Search Head

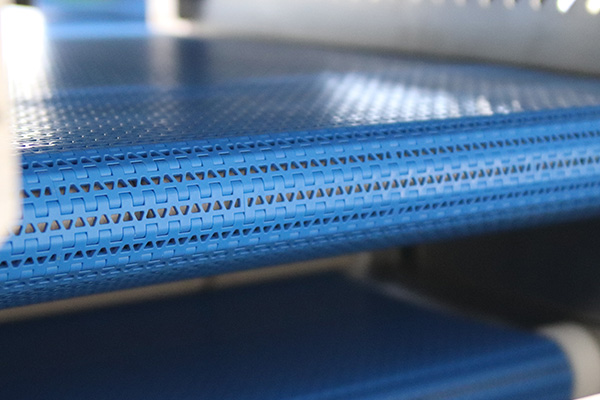

The IQ4 Rectangular Search Head Metal Detector is designed to be integrated within production lines or conveyor systems.

IQ4 SOD Conveyorized Metal Detector System

The IQ4 Conveyorized Stop on Detect (SOD) Metal Detector System is designed for large / bulk products with various size options.

X5 Bulkflow for Loose Food Inspection

Designed to be integrated into line with optional reject stations, the X5 Bulkflow X-ray is perfect for loose and free flowing products.

X5 XL800 X-ray Inspection System

Designed to be integrated into the production process at either the beginning to protect equipment or at the end to protect consumers, the X5 XL 800 is perfect for products such as meat in Euro crates or cheese in bulk boxes.

Why use X-ray Inspection?

Improved detection of metal

Detect smaller metal fragments compared to metal detectors systems

Detect bone and other physical hazards

Help improve quality by removing these unwanted contaminants which may still exist after secondary processing

Less susceptible to product conditions

X-ray systems are less susceptible to variations in temperature and humidity, as well as product presentation