Guide to Checkweighing

LOMA SYSTEMS® offers this guide to checkweighing to assist food and packaging companies in staying within government weights and measures legislation and helping eliminate over- and under-fill situations.

Weights and Measures

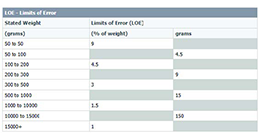

Limits of Error (LOE)

The tolerance below the stated weight within which the Canadian government permits a limited number of packs to be included in the batch. The graphic here shows both a table and a graph representing the limits for the most common pack weights.

Tolerable Negative Error (TNE)

The tolerance below the stated weight within which the European government permits a limited number of packs to be included in the batch. The ‘TNE’ table is the same as the ‘LOE’ table for Canadian legislation.

Maximum Allowable Variation (MAV)

The tolerance below the stated weight within which the American government permits a limited number of packs to be included in the batch. The ‘MAV’ table is different to the Canadian legislation.

Stated Weight

The label weight on the package is the quantity of product the consumer is paying for. Depending on the company and/or country, this is often referred to as ‘Label Weight,’ ‘Declared Weight,’ ‘Nominal Weight’ or sometimes ‘Target Weight.’ The LOMA checkweighers in the Canadian mode of operation use the ‘Nominal Weight’ terminology.

T1 Setpoint

The T1 setpoint is a dividing line between two weight zones. Weights falling below the T1 setpoint cannot exceed 2.5% of the batch; weights above the T1 setpoint can be of unlimited quantity, though the average of the batch must exceed the stated weight. The default T1 setpoint for Canadian weight legislation is sStated Weight’ or 1 x LOE.

T2 Setpoint

The T2 setpoint is a dividing line between two weight zones. There can be no weights accepted below the T2 setpoint; weights above the T2 setpoint (but below the T1 setpoint) cannot exceed 2.5% of the batch. The default T2 setpoint for Canadian weight legislation is ‘Stated Weight’ or 2 x LOE.

Lot

For the purposes of legislation, this is a continuous run of production, packaged ready for dispatch to the consumer (also commonly referred to as the ‘Batch’). Determination of the exact size of a ‘Lot’ or ‘Batch’ is made by a government inspector.

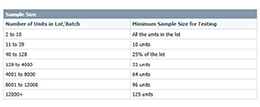

Sample Size

For the purposes of this explanation, the sample size is the number of packs from the ‘Lot’ or ‘Batch’ which the inspector chooses to test. The graphic here shows the minimum sample sizes called for by the weights and measures legislation, depending on the size of the batch or lot.

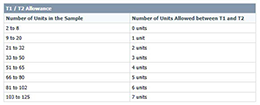

T1/T2 Allowance

For the purposes of this explanation, the T1/T2 allowance is the number of packages the inspector is permitted to accept between the T1 and T2 setpoints in the sample tests. This allowance is geared to the size of the sample itself and the graphic shows this allowance as called for by the weights and measures legislation.

Example

Reducing the overfill of a 450-gram pack by one gram, on a line producing 200 packs per minute running 16 hours a day for 230 days a year, would result in you saving enough raw materials to make an additional 98133 products.